Monitor and Analyze Production Data in Real-Time with Power BI

Manufacturing companies fail to utilize their data. Those risk falling behind. With the global manufacturing analytics market projected to reach $17.3 billion by 2025, there has never been a better time to embrace digital transformation.

Learn how Power BI, with its intuitive manufacturing dashboards transforms manufacturing through improved efficiency, informed decision-making, and data-driven growth.

The Manufacturing Industry is Ripe for Digital Disruption

Digital transformation is disrupting the manufacturing sector in profound ways. In 2020, the global digital manufacturing market was valued at $263 billion. It’s projected to reach $767 billion by 2026, growing at 19.48% annually (Mordor Intelligence).

Key drivers behind this growth include:

- Demand for higher productivity and efficiency

- Need for reduced operational costs

- Increasing automation and smart factory adoption

- Real-time visibility into production and supply chains

- Transition to data-driven decision making

Manufacturers that fail to embrace digital transformation risk losing market share. However, with the right analytics solutions, manufacturers can leverage their data as a strategic asset.

Unlocking the Power of Data in the Manufacturing Industry

Modern manufacturers generate vast amounts of data from sources like:

- Sensors, PLCs and industrial control systems

- MES, ERP, SCM and other enterprise software

- IoT and industrial automation systems

- Quality management and laboratory systems

- Equipment maintenance logs and records

- Inventory and warehouse management systems

Without proper analysis, this data holds little value. Manufacturers need ways to aggregate, process, analyze and visualize data from disparate sources to unlock its full potential.

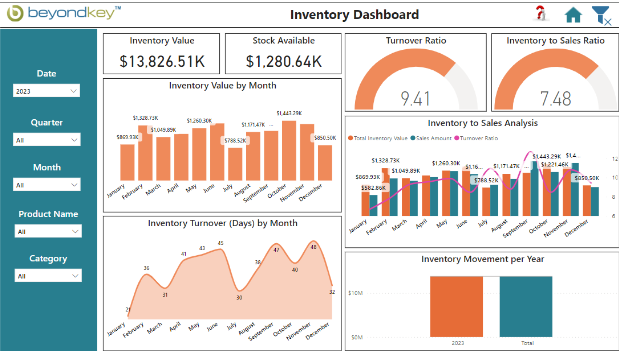

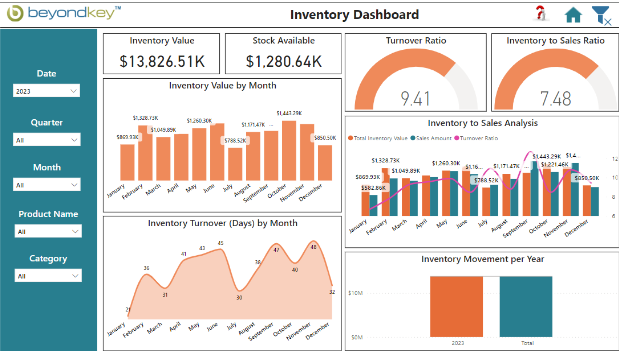

Power BI delivers an inventory dashboard which provides a good overview of the company’s inventory health. The dashboard shows that the company has a relatively high inventory turnover ratio and a low inventory to sales ratio, which are both positive signs. However, the dashboard also shows that the inventory value has been increasing in recent months, which could be a cause for concern.

Power BI provides intuitive dashboards for manufacturing that convert manufacturing data into actionable insights. Read on to learn how Power BI transforms key aspects of the manufacturing business.

Transform Supply Chain Visibility and Efficiency

Supply chains have never been more complex, nor have the stakes higher. Disruptions cost manufacturers nearly $184 million per year (BCG). Power BI allows you to integrate and analyze data from across the supply network to optimize every link in the chain.

With this Power BI’ manufacturing KPI dashboard, manufacturers gain real-time visibility into:

- Supplier performance metrics and compliance scoring

- Inventory levels by location, product, SKU

- Materials consumption rates

- Stockout risks and replenishment metrics

- Logistics costs, lead times and delivery KPIs

By monitoring these KPIs using manufacturing dashboards, manufacturers can identify inefficiencies and bottlenecks. This enables data-driven decision making to streamline supply chain operations.

Power BI helps manufacturers collaborate with suppliers and logistics partners to eliminate waste and delays. This creates more agile, resilient supply networks.

Boost Quality Management

Product quality is critical for manufacturing success. Power BI provides robust capabilities for early defect detection, root cause analysis, and continuous quality improvement.

Intuitive Power BI quality manufacturing dashboards display metrics like:

- First pass yield

- Rates of defects and returns

- Process capability indices

- Non-conformances by line, product, operator

- Reasons for rework and scrap

Statistical process control charts highlight anomalies in real-time, allowing quick corrective actions. Manufacturers can also drill down into dashboards to pinpoint the root causes of recurring defects.

By monitoring quality trends in Power BI, manufacturers drive higher product reliability, reduce rework and warranty claims, and ensure customer satisfaction.

Optimize Production Operations

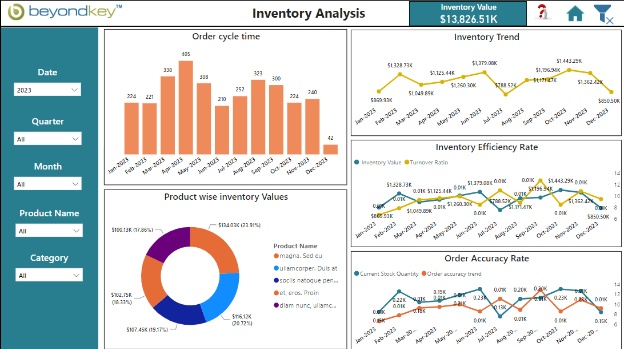

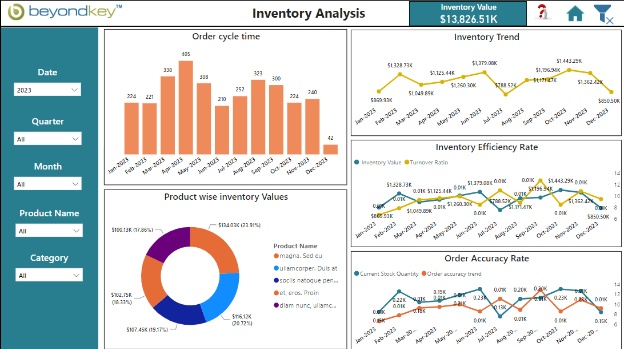

Maximizing productivity and efficiency has always been vital for manufacturers. Power BI delivers capabilities to optimize production operations including:

- OEE monitoring by line, shift, product

- Schedule attainment tracking

- Identification of downtime causes

- Bottleneck analysis

- Cycle time variability monitoring

- Labor productivity KPIs

- Energy usage tracking

The rich analytics provided by Power BI and its various manufacturing dashboard examples enable manufacturers to minimize downtime, reduce changeover times, balance workloads, streamline processes, and drive continuous improvement.

You get an inventory analysis dashboard from Power BI. This dashboard suggests a business’ inventory, which is either tying up capital and increasing costs or otherwise. Manufactures can improve their inventory efficiency by reducing order cycle time, improving order accuracy, and better managing its product mix. All with the help of this powerful inventory analysis dashboard

Power BI also makes it easy to compare performance across multiple plants to replicate best practices company-wide. This results in leaner, more agile production.

Enable Proactive Maintenance

Unplanned downtime cripples manufacturing productivity. With preventive maintenance analytics from Power BI’s manufacturing dashboards, manufacturers can reduce downtime by up to 12% (Deloitte).

Power BI extracts asset health insights from:

- SCADA and equipment sensors

- Maintenance work orders and histories

- Repair logs and costs

- Sensor streams and IoT data

Metrics like mean time between failures and time-to-repair inform optimal maintenance schedules. Performance anomalies trigger alerts for early investigation.

By connecting all maintenance data in Power BI, manufacturers gain a unified view of asset health. This powers predictive maintenance programs that keep equipment running reliably.

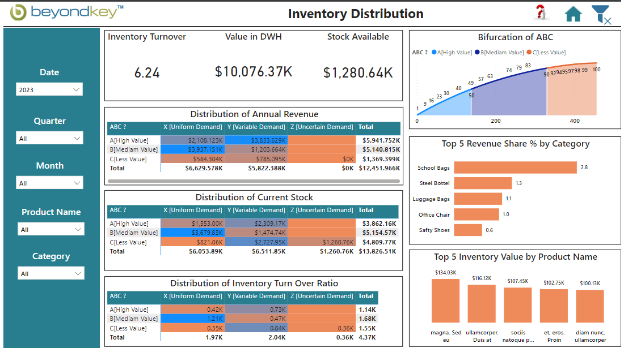

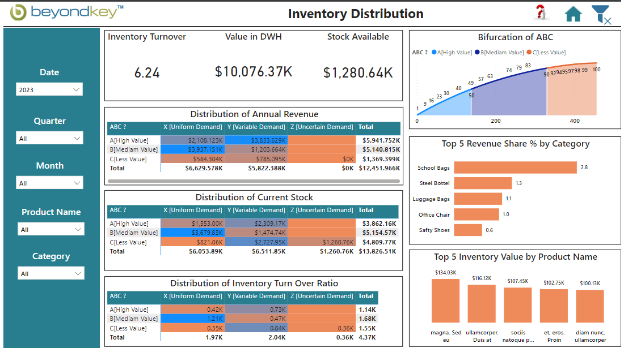

Inventory Distribution Dashboard

Power Bi delivers a powerful dashboard– Inventory distribution dashboard. This displays information about the inventory levels of different products and categories. The dashboard is divided into several sections:

- Inventory Turnover: Shows the inventory turnover ratio for different time periods. It’s a measure of how often inventory is sold and replaced. A higher ratio indicates inventory is being turned over more quickly, which is considered a good thing.

- Value in DWH: This section shows the total value of inventory in the data warehouse.

- Stock Available: This section shows the total amount of stock that is available for sale.

- Bifurcation: This section shows the distribution of inventory value across different categories. ABC categorization is a method of classifying inventory items based on their importance. Items are the most important, B items are moderately important, and C items are the least important.

- Distribution of Annual Revenue: This section shows the distribution of annual revenue across different product categories.

- Distribution of Current Stock: This section shows the distribution of current stock levels across different product categories.

- Top 5 Inventory Value by Product Name: This section shows the top 5 products in terms of inventory value.

- Distribution of Inventory Turn Over Ratio: This section shows the distribution of inventory turnover ratios across different product categories.

Overall, the inventory distribution dashboard provides various insights into a company’s inventory’s health. By analyzing the data in this dashboard, companies can make informed decisions about how to manage their inventory more effectively.

Deliver Faster Insights with Beyond Key

Most manufacturers struggle with long data preparation and reporting cycles using traditional analytics tools. Beyond Key’s variety of manufacturing dashboard examples offers accelerated analytics through an exclusive partnership with Beyond Key.

The Beyond Key Direct Data Platform converges disparate data sources in a low-code environment. This eliminates repetitive ETL tasks so manufacturers can go from raw data to insights in minutes instead of weeks.

With Beyond Key and Power BI together, manufacturers gain:

- 50-80% faster time-to-insight

- 10X data compression

- Scalable architecture that keeps pace with data volumes

- Lower TCO compared to legacy analytics tools

Plan for Growth with Forecasting and ‘What-If’ Modeling

Data-driven demand planning is key for manufacturers seeking growth. Power BI’s manufacturing dashboards equip business users to perform forecasting and simulations without IT support.

Intuitive forecasting tools analyze historical trends in:

- Demand by product, channel, geography

- Lead times, sales cycles, inventory velocity

- Macroeconomic factors, seasonality

- Marketing campaigns and price elasticity

Users can override statistical forecasts with bottom-up projections. Running ‘what-if’ simulations allow planning for diverse demand scenarios.

By integrating this analysis into production planning and sales processes, manufacturers drive efficiencies while positioning for growth with Power BI’s manufacturing dashboards.

Drive Data Culture Through Democratization

For organizations to become truly data-driven, they must foster a culture of data-based decision making at all levels. Power BI makes data accessible to operational workers through interactive manufacturing dashboards.

Plant managers can monitor production KPIs in real time. Maintenance teams access asset health metrics and histories. Operators get quality and workflow insights.

By providing users self-service access to visual analytics, Power BI drives adoption of data best practices. This creates a workforce empowered by data at scale.

Gartner finds that organizations with data-driven cultures are 64% more likely to exceed business goals. With Power BI, manufacturers can democratize data and nurture data-centric cultures focused on continual improvement.

Realize the Full Potential of Your Manufacturing Data

As a Microsoft Solutions Partner, Beyond Key helps manufacturers unlock the true potential of their siloed data locked inside disparate data sources. Our Microsoft certified experts offer solutions and services custom built for modern manufacturers and help them achieve digital excellence.

Our expert professionals are champions when it comes to satisfying the consulting needs of manufacturers who are looking to create agile factories with resilient supply chain and automated floor operations for seamless production and factory operations.

We handle data integration from hundreds of sources using the latest ETL and data warehousing techniques. Our Power BI manufacturing dashboards deliver role-based insights that drive productivity, quality, growth and innovation throughout your organization.

Visit Beyond Key to learn more about our Power BI analytics solutions, view sample manufacturing dashboards, and request a demo.

It’s time to unlock the 4th industrial revolution with the power of data intelligent solutions with Beyond Key.

As a Microsoft Solutions Partner, Beyond Key leverages the full suite of Power BI capabilities tailored to the unique needs of manufacturers. Contact us today to start your Power BI analytics journey.

Our team brings deep domain expertise with manufacturing metrics dashboards and processes. We handle data integration from hundreds of sources using the latest ETL and data warehousing techniques. Our Power BI manufacturing dashboards deliver role-based insights that drive productivity, quality, growth and innovation throughout your organization.

It’s time to transform manufacturing by unlocking the power in your data with Beyond Key.