Why Dynamics 365 Business Central Is the Ideal ERP Platform for Manufacturers

Managing a manufacturing business is challenging, even when most of the legwork is carried out by heavy machinery.

Keeping the inventory stocked per the business’s requirements and ensuring custom orders meet the production timeline of clients demands a flawless workflow from manufacturers.

But this is not to say that this level of management cannot be achieved. Provided that the management is structured appropriately, the right ERP for manufacturing will integrate the production and financial aspects of manufacturing.

It will provide a 360-degree view of the manufacturing plant from the shop to the top. And this is where Business Central comes in.

The ERP platform enables you to automate redundant tasks and carry out all the essential management tasks in a unified interface.

More importantly, the featured manufacturing functionality offers business owners and managers full visibility and control over the plant, making day-to-day management simple and straightforward.

We detail the functionality and benefits of Business Central in this post for your convenience.

What is Business Central?

What is Business Central?

Microsoft Dynamics 365 Business Central is one of Microsoft’s newer offerings, featuring a full-fledged NAV functionality in a SaaS environment. The SMB ERP platform is the future of the Microsoft Dynamics NAV roadmap and offers on-premise, cloud, and hybrid development options.

It’s important to note that the solution is part of the wider Microsoft Dynamics 365 suite. The all-in-one approach allows businesses to control manufacturing and finances fully while ensuring that production is secure and menial tasks are completed automatically.

Manufacturing Functionality in Dynamics 365 Business Central

One of the best things about Business Central for manufacturing is that its all-in-one approach allows businesses to seamlessly integrate their manufacturing module with other business processes such as inventory, customer service, accounting, and marketing.

The Business Central manufacturing module can be invaluable since it offers managers access to the latest production data when they perform their daily tasks.

This way, the Dynamics 365 Business Central Manufacturing module allows managers to analyze the company’s status fairly and accordingly navigate the business for growth.

As mentioned earlier, Business Central is designed for small and medium businesses, enabling them to connect the data from the various business areas and store it in a single, secure database.

In other words, the manufacturing team always has access to all the details about the quotes, routes, and orders.

With the Dynamics 365 Business Central Manufacturing module, streamlining the manufacturing process from planning and scheduling to inventory and distribution becomes more manageable.

Here’s a look at the specific functions the Business Central manufacturing module offers:

1. Production Orders

Creating and managing production orders becomes straightforward with the simple interface, which also offers one-click access to all the order details – from installation details and guarantees to workforce and inventory.

Business Central for manufacturing allows you to set up various types of production orders and determine the requirements for that order with ease.

2. Agile Manufacturing

ERP for manufacturing often comprises the agile method to improve business efficiency. The nice thing about Business Central is that the agile method is integrated into the tool right out of the box.

3. Version Management

Manufacturing is a multi-faceted process, and it is common for businesses to lose track of things. The client’s changes in requirements, invoices, and materials are only a few of the many aspects that a manufacturing company must organize.

With all the different versions of the invoices, bills of materials, routings, and other requirements stored on Business Central, it becomes easy for the manufacturer to follow them closely.

4. Inventory Planning

Creating a product is impossible without the raw material. While sourcing sounds simple in theory, planning how to acquire material for the right price can be challenging with the ever-changing demand forecasts.

Business Central features a production module that acts as a planning master, allowing you to streamline this process and make ambitious targets achievable.

5. Capacity Planning

The ERP platform allows you to easily make a system calendar and include the required parameters and details. Users can attach several machine centers to a single work center.

Furthermore, with Business Central, it’s easy to manage shift capacity, process changes in the capacity, and update the production schedule.

6. Machine Centers

The Business Central manufacturing module features machine centers, allowing businesses to digitally manage their machines’ capacities. Further, the module allows storing default information about the manufacturing process and accessing all the data seamlessly in the ERP.

7. Production Bill of Materials

With Business Central, calculating standard costs and creating bills of materials becomes a breeze. The featured production BOM makes it simple to track the input quantities by dimension and quantity.

8. Supply Planning

Making production and purchase orders automatically is no longer a pipe-dream with Business Central. Besides allowing a business to place these orders automatically, it can also send action messages to balance supply and demand.

Further, the platform supports bucketed and bucket-less requirements planning, allowing businesses to manage their clients in a sophisticated way.

9. Sales and Inventory Forecasting

The intelligent ERP platform analyses a business’s historical data to forecast the expected number of sales and stock-outs. With these insightful forecasts, the business can easily create replenishment requests for its vendors.

10. Standard Cost Worksheet

The larger the business and the wider the client base, the more challenging it becomes for the business to maintain accurate inventory costs.

Business Central offers a spreadsheet-like interface to help company controls work out the standard cost updates.

11. Assembly Management

One of the most helpful features of Business Central is that it enables businesses to specify a list of raw materials, resources, sellable items, and more to create an assembly bill of materials. These orders make it simple for the business to replenish the required items as necessary.

What’s more impressive is that the platform allows controllers to capture a customer’s requirements for the bill of materials straight from the quotes, order lines, and blanket orders.

Overall, Dynamics 365 Business Central’s manufacturing module is easy to learn and use and offers controllers flexibility that they may not have thought achievable.

Implementing it in workflows is effortless for businesses of all sizes, and its workings can be expanded down the road as a business’s needs change.

How to Get the Module of Business Central Manufacturing

Getting access to some of the functions and modules of Business Central requires businesses to buy specific plans and increase their monthly budget. However, any manufacturer worth its salt will need a robust ERP solution to manage its projects, and Business Central is worth the price with its array of features.

The platform is available in two plans: Essentials and Premium.

The Essentials plan provides access to all the basic features a manufacturer will need, including customer service, project management, finance, supply chain, warehouse, and human resources.

The Premium plan includes two additional modules, significantly improving the tool’s management capacity.

The manufacturing management and service modules allow controllers to manage aspects such as capacity planning and production order management easily and efficiently.

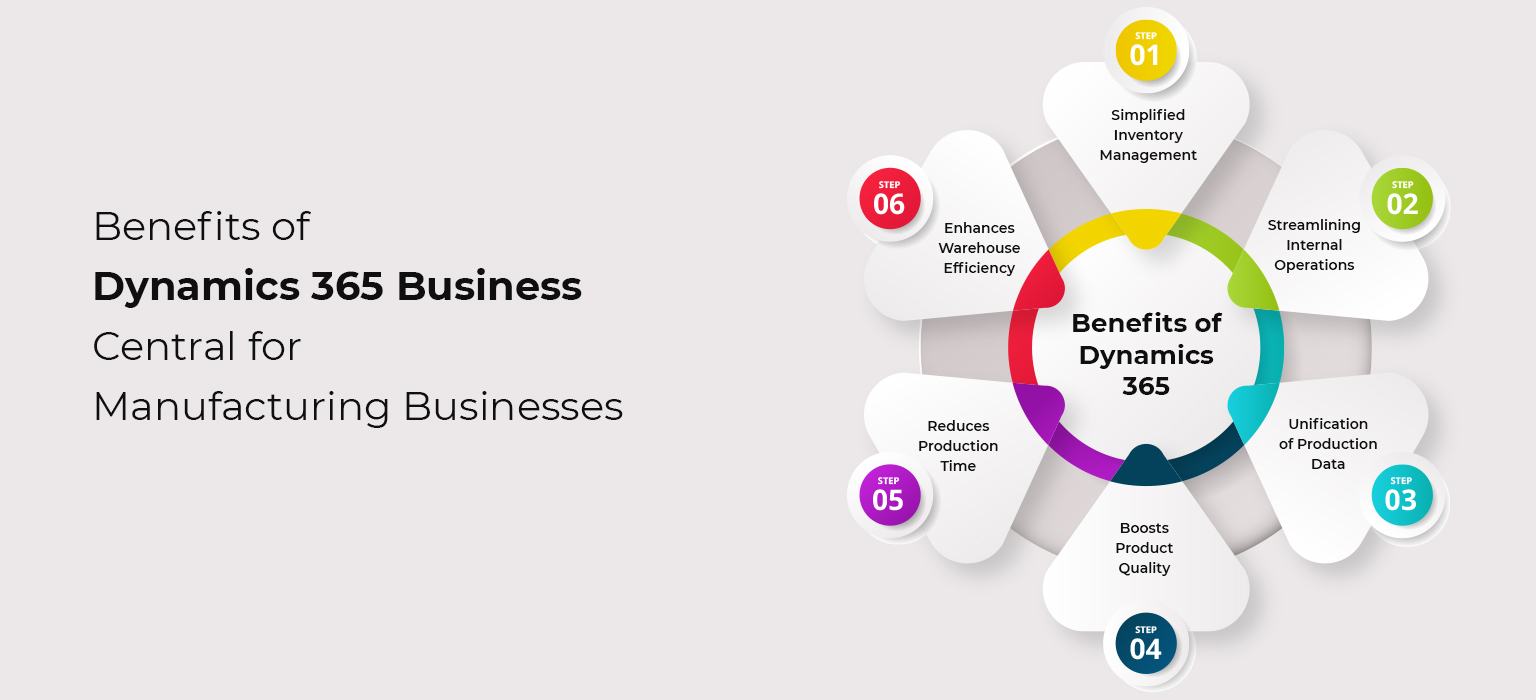

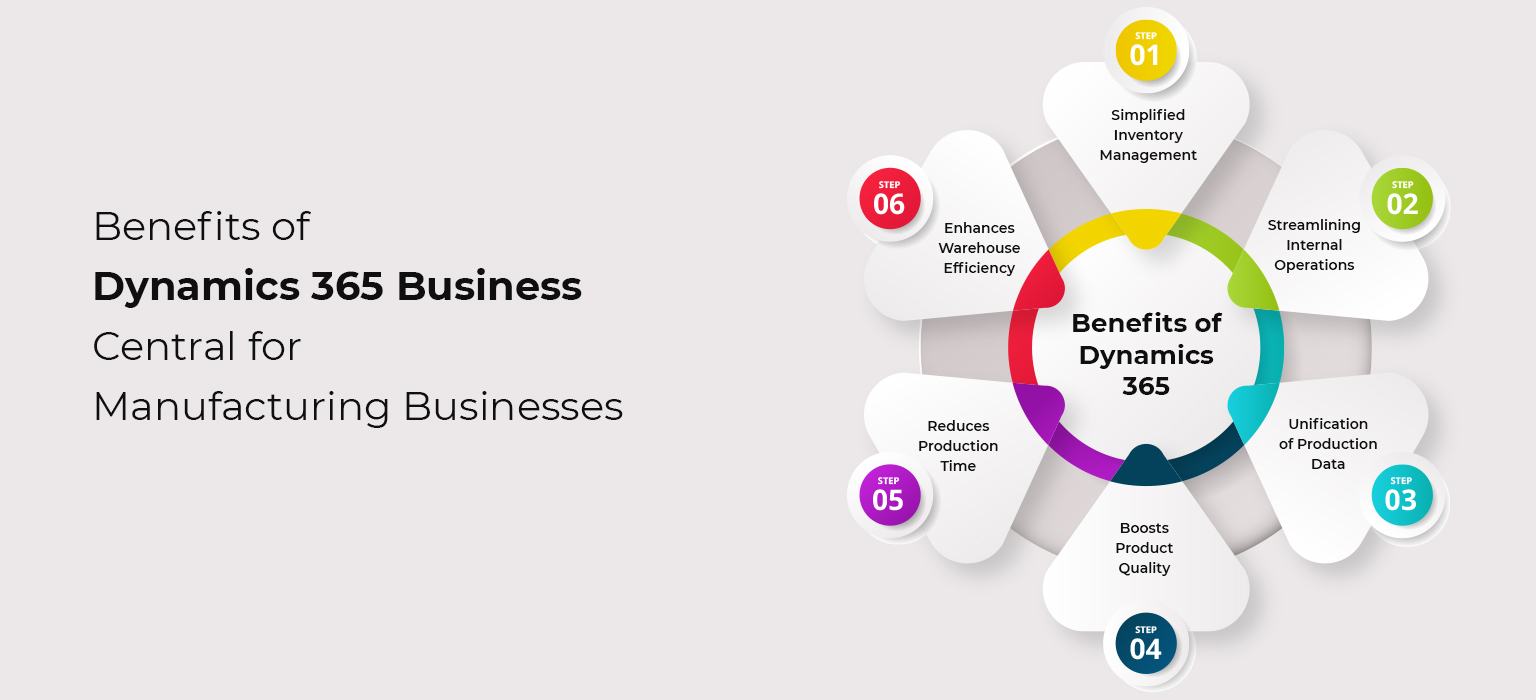

Benefits of Dynamics 365 Business Central for Manufacturing Businesses

While the manufacturing module may be the primary attraction of Business Central, the platform’s core also features functionality such as financial management, supply chain management, project management, sales, HR, and more.

In other words, we still haven’t fully analyzed the benefits of Dynamics 365 Business Central for manufacturing businesses. Here are some of the top benefits of using Business Central for SMBs:

1. Simplified Inventory Management

View an updated list of the items in stock with a few simple clicks seconds after new items are added to it. At a glance, you will be able to see how much of what item is in storage and how many of them are on order.

What’s more, Business Central also predicts an estimate of when the stock will run out, allowing the business to plan replenishments accordingly.

2. Streamlining Internal Operations

As mentioned earlier, employing Business Central allows the business to store all data in one consolidated place. In other words, when a manager makes an update, the entire team will have access to it and can act accordingly.

Furthermore, the sales forecasts ensure that the business can efficiently handle future orders and sales, making workflows more cohesive and collaborative across the organization. This way, operating costs are also reduced.

3. Unification of Production Data

Consolidating the production data allows Business Central to analyze the business’s trends, owing to the business intelligence that comes built in. The analysis of the production, product performance, inventory, and supply chain data offers insights that enable the business to improve the customer’s experience. .

4. Boosts Product Quality

Using Business Central, a business can monitor the quality status of all its products. The real-time reports concerning the shifts, machines, and components, among others, help ensure that your customers always get high-quality products.

5. Reduces Production Time

Since the business can capture a customer’s requirements in their bill of materials directly from the quote, the orders align seamlessly in the assembly-to-order process. This way, there is no need for slow and excessive customer correspondence, which results in a shorter production time, helping save time and money.

6. Enhances Warehouse Efficiency

Business Central boasts several features that help you run your warehouse efficiently. Besides streamlining the process of receiving and storing materials, you also get access to recommendations about where to place the items for optimal space and time utilization.

Manufacturers and ERP Software

Owners of small and medium-sized manufacturing businesses understand that staying competitive is a prerequisite to appealing to any client in the marketplace. Generally, clients demand quick responses and ask the business to deliver new products in short spans.

The manufacturing process is multi-faceted and involves several steps and sub-steps from shop to shipping – and this is only the start. Top-tier manufacturers take the high road and go the extra mile to offer their clients the best custom-designed products.

In today’s competitive, low-margin, high-effort market, the success of the manufacturing business, regardless of its size, depends on its ability to deliver these custom orders to customers. If a manufacturer does not keep a close eye on all ongoing processes, productivity can take a massive dip.

In situations like these, the success of the manufacturing business, regardless of its size, depends on its ability to deliver these custom orders to customers. The ability to deliver, in turn, depends on the efficiency of internal operations, which is why picking an ERP platform is no small decision.

The right ERP platform can mean the difference between the success and failure of the business.

Growing manufacturing companies typically fall into one of three categories. The business may be:

-

- Relying on a legacy enterprise planning software that does not work perfectly or scale easily;

- Employing an entry-level management solution that involves several manual processes and third-party integrations; or

- Not using the software at all – this is typically when the business is small.

When it comes to picking an ERP solution, the size of the business is a secondary factor. The idea behind getting an ERP solution is to help the business grow in size and improve its efficiency.

Contemporary manufacturing businesses need the right software tools to thrive in today’s competitive market. The best solution is a single dedicated solution that simplifies every step of the operations, from creating quotes to assembling orders and shipping.

And ERP software is designed to meet these narrow requirements.

How Business Central Helps You Scale Your Small Manufacturing Business

Scaling a manufacturing business becomes more achievable with Business Central since the cloud-based solution allows businesses to scale their operations flexibly.

The monthly payment model removes the need for businesses to pay huge amounts upfront – like an on-premise solution – which in turn allows the business to get operations up and running quickly.

What’s more, Business Central can integrate with a range of applications and solutions, which means businesses get access to a customized solution without much hassle.

Whether your business uses Microsoft applications found on App source or designs custom apps with Power Apps, you will be set to use them alongside Business Central in a matter of minutes.

But the best part is that the cloud ERP allows business owners to run their manufacturing business on the go from any device. The feature-loaded platform will help you pinpoint what is working and what isn’t, after which you can continually optimize internal operations.

What is Business Central?

What is Business Central?